batch pyrolysis reactor

Results from the reduced-order models are compared to bubbling fluidized bed reactor experiments using various biomass derived feedstocks. Wood residues were pyrolysed in a cylindrical batch reactor at temperatures 300-350 400-450 and 500-5500C and the organic were characterised using a gas chromatograph GC fitted with a flame ionisation detector FID.

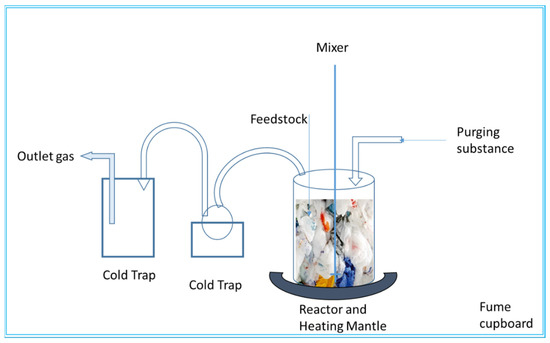

Schematic Of Process And Semi Batch Reactor Used For The Catalytic Download Scientific Diagram

These do not run continuously and this is why their processing capacity is not as high as a fully continuous waste tire pyrolysis plant.

. Batch-based semi-continuous tire pyrolysis concept. The current research has been carried out on a reactor to improve the two important factors for obtaining better product yield such as heating rate and residence time period. Order 6 YRS CN Supplier 49 20 great service.

1Ton per batch pyrolysis plant with 2 distillation tower for waste tyre and plastic pyrolysis 2850000-3450000 Set 10 Sets Min. The plant has two pyrolysis units each of which consists of a horizontal axis rotary type batch mode reactor 45 tonsrun that operates at 420 C under 003 bar pressure. Manufacturing Process The manufacturing process refers to the processes used for welding or joining various components together.

The most notable compounds in the wood vinegar and tar were. After pyrolysis you need to wait to cool down and then discharge the carbon black. Beston mainly offers three types.

The BLJ-06 6 TD BLJ-10 8-10 TD batch operating pyrolysis plant can handle these raw materials such as waste tires plastics rubber oil sludge and the final products are fuel oil carbon black steel wire for tires. The oil char gaseous and steel cord product yields were 45 wt 35 wt 10 wt and 10 wt respectively at optimum reaction conditions. Longer service life and safer Continuously operating reactors such as Rotary and Auger reactors have been covering a wide range of industrial applications for decades.

Furnace The reactor is inserted in a pit furnace with a circular cross-section of 100 cm external diameter and 98 cm height. Laboratory scale pyrolysis reactor The semi-batch reactor shown in Fig. View the following specifications.

The aim of this study is to model a batch reactor to be used for plastic pyrolysis. The reactor is heated by a 1500 W electrical coil coupled to a programmable controller that regulates final temperature. A convergent top exhaust chute condensation chamber L shaped oil outlet three induction coil and a temperature controller.

In our last article Part I we addressed the question of how the advantages of a classic batch-reactor process design can be combined with those of a continuous process mode. A comparative study Thermo-catalytic pyrolysis is considered as a promising process for the chemical recycling of waste polymeric materials aiming at converting them into their original monomers or other valuable chemicals. Continuous Pyrolysis Reactor Working Method As mentioned for the batch pyrolysis system you need to pre-heat first.

Order 3 YRS CN Supplier Contact Supplier Compare 1 6 Mixer Jacket Heating Lab Pyrolysis Equipment Stirred Tank Reactor 75600-78700 Unit 1 Unit Min. This repository contains Python code for running batch and continuous stirred tank reactor CSTR models to estimate thermochemical biomass conversion at fast pyrolysis conditions. Pyrolysis was performed at 69 bar 100 psi at different temperatures from 400 to 600 C with heating rates of 4 Cmin.

The reactor design parameters are a maximum temperature of 800 C at 3 barg pressure and 700 C at 7 barg. This paper tries to assess process yields by performing conventional pyrolysis at an elevated pressure of energy sorghum using a high-pressure batch reactor and evaluates the corresponding product characteristics respectively. The pyrolysis batch reactor was designed using Catia software with the overall dimension of 400 X 200 X 458 cms as shown in the Figure 2.

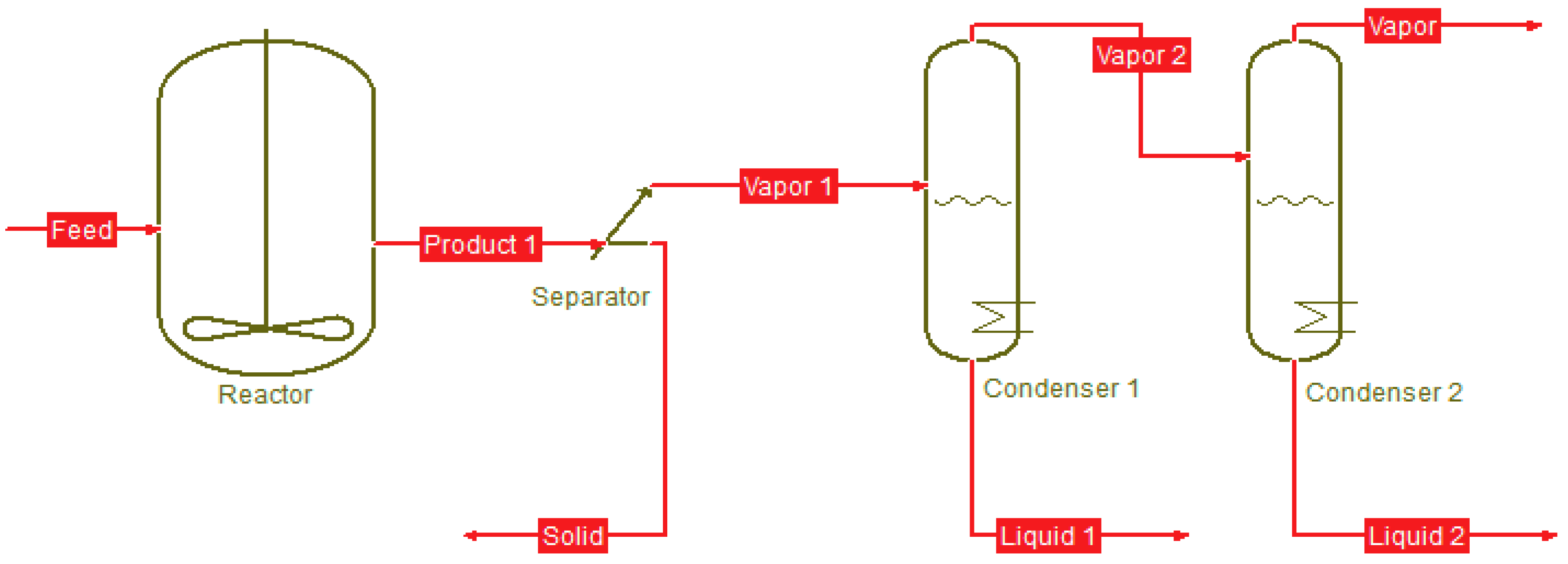

Pyrolysis reactor is the most concerned key part related to pyrolysis business. 1 feeding system where the raw material is typically heated and melted with the liquid outflow being fed into the reactor 2 a pvc cracking at 350c is required for feedstocks containing pvc 40 3 pyrolysis reactor operating at temperatures between 350 and 650c. Most of the pyrolysis reactor technologies consist of three main sections.

XIELI PRODUCT SPECIFICATIONS 1 Raw Material Can be Used In Pyrolysis Machine 2 Final Production and Usage 20-80 Plastic Oil 12-72 Carbon Black 3 Layout Drawing Company Profile Why Choose Us After-sale Service Pre-. This batch type does not need pre-treatment devices and the raw materials can be put into the reactor directly. Thermo-catalytic pyrolysis of polystyrene in batch and semi-batch reactors.

The reactor consists of two cylinders. 1 is a stainless steel hollow cylinder of 200 mm height 80 mm inner diameter and 4 mm thickness. Choosing a good-quality reactor not only means a long time warranty but also help to save repair and maintenance cost.

It can work continuously for 24 hours a day. Batch Type Plant Pyrolysis Reactor Equipment Converting Plastic To Fuel Furnace Oil NEW Manufacturer. Consequently four experiments with different heating and cooling cycles are done using an empty pyrolysis batch.

They have been tried and tested and are state-of-the-art. The net internal volume is about 51 l with 33 cm diameter and 60 cm height. In the current article Part II we address some characteristics and advantages of a batch reactor regarding the thermochemical reactions and their effects on the end products.

In pyrolysis process pyrolysis reactor design is one important key because it determines the product distribution both qualitatively and quantitatively. Design and fabrication of a fixed-bed batch type pyrolysis reactor for pilot scale pyrolytic oil production in Bangladesh July 2016 IOP Conference Series Materials Science and Engineering 1841. However there is no need to wait for cooling down the reactor in a continuous pyrolysis unit.

This also applies to batch-based reactor concepts. We refer to the. Alcohols acids furans phenols aldehydes and ketones.

Batch configuration is designed to process material in batches. Beston Waste Pyrolysis Reactor Installed in Turkey.

The Construction Of Pyrolysis Gasifi Cation Batch Reactor Download Scientific Diagram

Schematic Of The Batch Pyrolysis Reactor Download Scientific Diagram

Safety Procedure Regulation Of Batch Pyrolysis Process Beston Pyrolysis Plant

Semi Batch Pyrolysis Reaktor Adapted From Reference Erliyanti Et Al Download Scientific Diagram

Batch Pyrolysis Reactor Used For Objective 2 The Various Components In Download Scientific Diagram

Stainless Steel Batch Reactor Unit Used For Pyrolysis Download Scientific Diagram

The Schematic Ow Of The Vacuum Pyrolysis Batch System T Thermocouple Download Scientific Diagram

Pilot Scale Batch Pyrolysis Reactor Download Scientific Diagram

Batch Apparatus For Plastic Biomass Co Pyrolysis 1 Reactor 2 Pid Download Scientific Diagram

Processes Free Full Text Recent Advances On Waste Plastic Thermal Pyrolysis A Critical Overview Html

Energies Free Full Text Experimental Analysis Of Temperature Influence On Waste Tire Pyrolysis Html

Schematic Of The Batch Pyrolysis Reactor Download Scientific Diagram

Design Fabrication And Performance Test Of A Fixed Bed Batch Type Pyrolysis Plant With Scrap Tire In Bangladesh Sciencedirect

Processes Free Full Text Simulation Of Batch Slow Pyrolysis Of Biomass Materials Using The Process Flow Diagram Coco Simulator Html

Schematic Diagram Of Pyrolysis Batch Reactor 1 Steel Cylinder Download Scientific Diagram

Stage I Pyrolysis Reactor Batch And Pyrolysis Vapour Condensation Download Scientific Diagram

The Flow Diagram Of The Pyrolysis Reactor Color Figure Available Online Download Scientific Diagram

Pyrolysis Of Waste Polyethylene In A Semi Batch Reactor To Produce Liquid Fuel Optimization Of Operating Conditions Sciencedirect

0 Response to "batch pyrolysis reactor"

Post a Comment